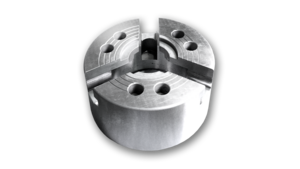

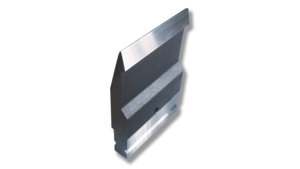

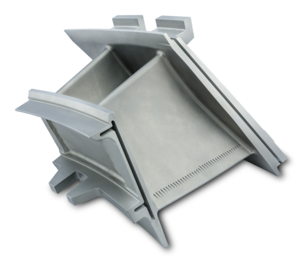

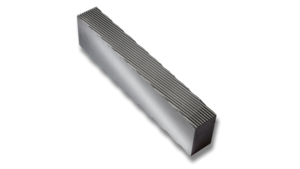

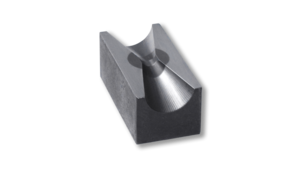

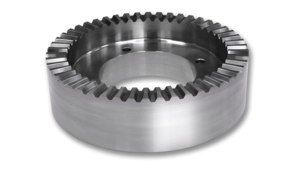

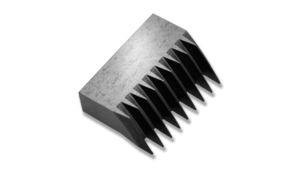

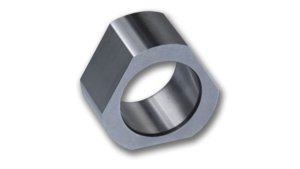

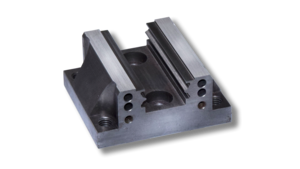

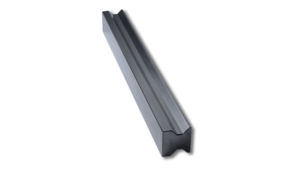

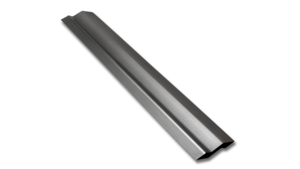

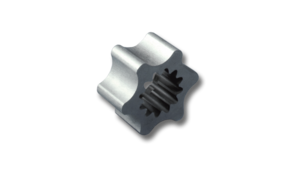

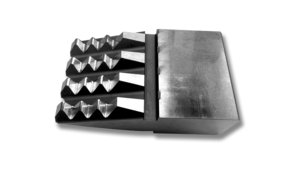

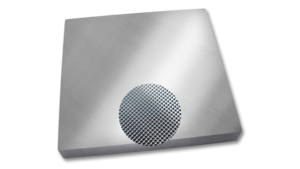

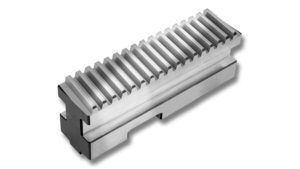

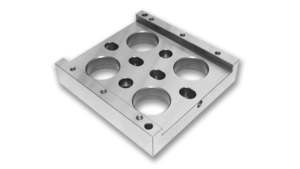

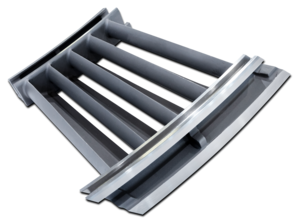

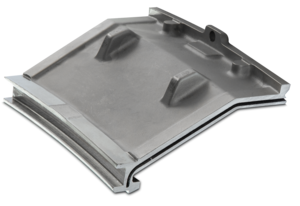

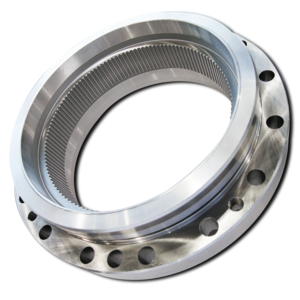

Workpieces

Flat and Profile Grinding machines

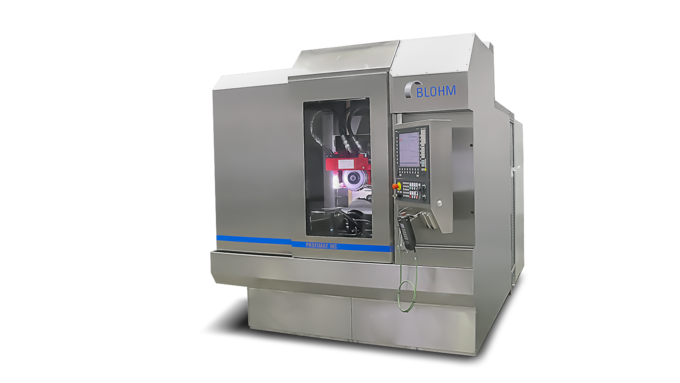

The competitive 3 axis entry level machine for high precision surface and profile grinding

- Defined scope of supply

- Siemens MC 1720 control

- BLOHM single piece production with graphical operator guidance

- Grinding technologies: Reciprocate grinding, Creep feed grinding

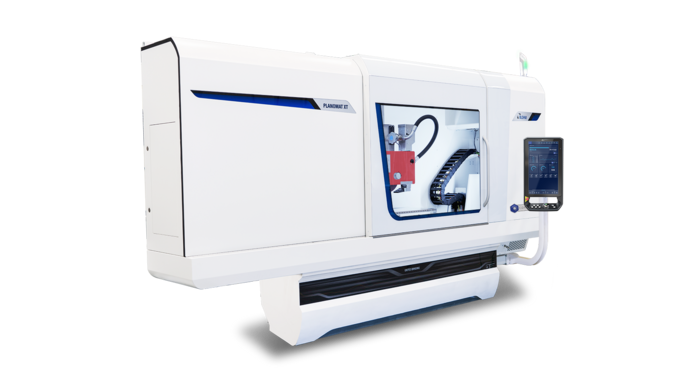

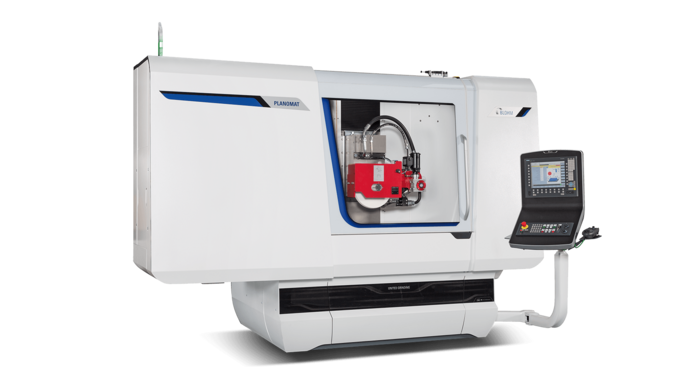

Higher axle speeds, higher accelerations and increased system rigidity – combining these improved influencing factors consistently increases productivity while at the same time increasing component quality. These features feature the PLANOMAT XT as a universal, robust and powerful flat and profile grinding machine, which consistently builds on the experience and quality of the very successful PLANOMAT HP.

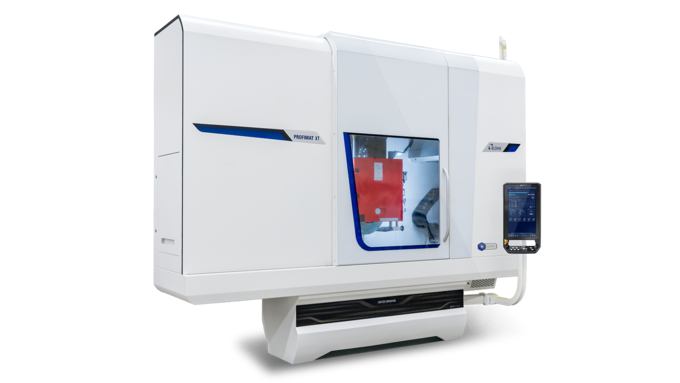

Are you looking for a grinding solution for the production of large lot sizes or batch production? Then the PROFIMAT RT could be the right machine for you. This highly efficient production machine with a traveling column design is equipped with a rotary indexing table. This enables workpiece handling in parallel with the primary processing time, i.e. continuous, simultaneous loading and unloading during the grinding process. Low setup costs combined with high efficiency and the possibility of simple adaptation of automatic workpiece change systems set benchmarks in modern and cost-effective production.

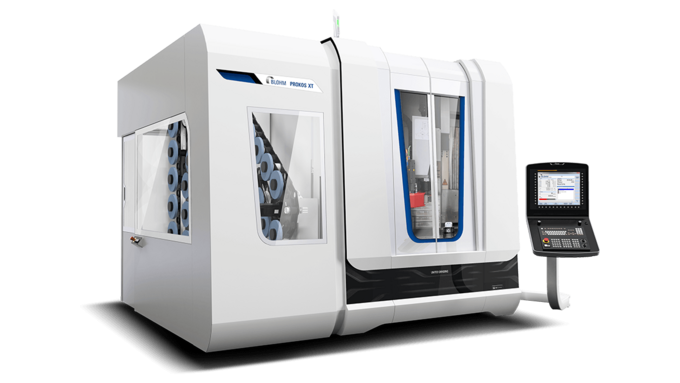

Higher main axis speeds, greater acceleration and increased system rigidity – the combination of these consistently optimized essential performance characteristics means increased productivity while improving component quality. These features distinguish the PROFIMAT XT as a robust and effective production grinding machine that consistently builds on the experience and quality of the highly successful PROFIMAT MT.

In applications where the production process requires high stock removal rates, the flexible and powerful PROFIMAT MT is the right choice. A driving power of up to 60 kW and cutting speeds of 170 m/s guarantee maximum productivity – for both conventional and CD/IPD grinding processes, as well as for all high-speed grinding processes with CBN. Pretensioned anti-friction guideways in all machine axes guarantee the necessary system rigidity and reduce maintenance requirements.

Whether precision, profile, internal or external cylindrical grinding – the PROFIMAT MC is a highly efficient grinding centre for any application. This extremely compact traveling-column machine offers everything that modern production solutions require, with a machine width of just 2000 mm. Different spindle variants enable diverse applications: The five-axis CNC profile grinding machines in the series can optionally be equipped with a horizontal spindle for drive capacities up to 60 kW as well as a stationary or an NC-swiveling vertical spindle with grinding spindle speeds of up to 60,000 revolutions per minute.

The PLANOMAT HP combines reproducible precision and powerful speed with high flexibility – the ideal combination for efficient profile grinding. The robust, inherently stiff design with 3-point installation ensures the exactness of the modular PLANOMAT HP machines. A driving power of up to 24 kW combined with high-precision, digitized ball-type drives guarantees high infeed speeds and accelerations. Table speeds of up to 40 meters per minute reduce grinding times and increase productivity. Almost maintenance-free linear guideways and the highly efficient, lifetime-lubricated grinding spindles reduce the maintenance requirement to a minimum.