5-Axis Machining Centres HF

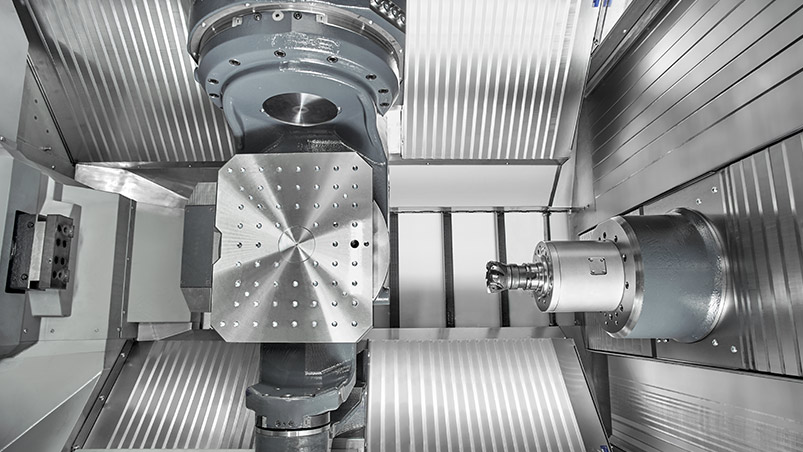

Horizontal 5-axis machining center with fifth axis provided by the workpiece

The HF series

The new HF series from HELLER – that means dynamic and productive machining in five axes. It is based on the typical HELLER DNA – highest quality, perfect productivity and absolute reliability in everyday use throughout the machine’s entire life cycle – making it optimally equipped for the exacting requirements of modern production processes. Highly productive and flexible, easy to operate and maintain, for table loading or use with a pallet changer: the HF series is made for high output with minimal handling requirements. Made to work.

- Dynamics: directly driven rotary axes, small mass moment of inertia from the swivelling rotary table, constantly high speed of the AB-axis thanks to the minimal mass moment of inertia, direct drives in the two rotary axes A and B

- One basis – two versions: identical machine structure of pallet changer and table loading version, automatic pallet changer for series production, proven lift-and-swivel principle

- All spindles are designed for a 10 min duty cycle at S6 40%

- Speeds of up to 18,000rpm and up to 354Nm torque

- Maintenance-free motor spindles

- Optimal traversing dynamics

- High precision and repeatability: high-speed tool changer with two fast NC axes for dynamic stroke and swivel movement

- Fully customisable to your requirements in terms of spindle, spindle taper, tool magazine and chip disposal

- Attractive price/performance ratio

- Highest load capacity and reliability

- High availability thanks to sophisticated safety concept and HELLER services

Pallet changer concept for series production

- Optimally suited for series production with and without workpiece automation due to robust lift-and-swivel principle

- Up to 550kg (HF 3500) or 750kg (HF 5500) load capacity per pallet

Table concept for direct loading

- Ideal for manufacturing small batch sizes and frequently changing machining tasks

- New machine concept provides perfect access to the work area

- Comfortable workpiece handling from the ergonomically optimised front of the machine

- Operator panel that can be swivelled from the work area door to front door

A swivel axis and B rotary table

- Direct driven and cooled A and B axis for excellent dynamics and highest precision

- Excellent stiffness due to combined axial/radial bearings with integrated, absolute and direct measuring systems in A and B

- Compact build allows high permissible tilting moments