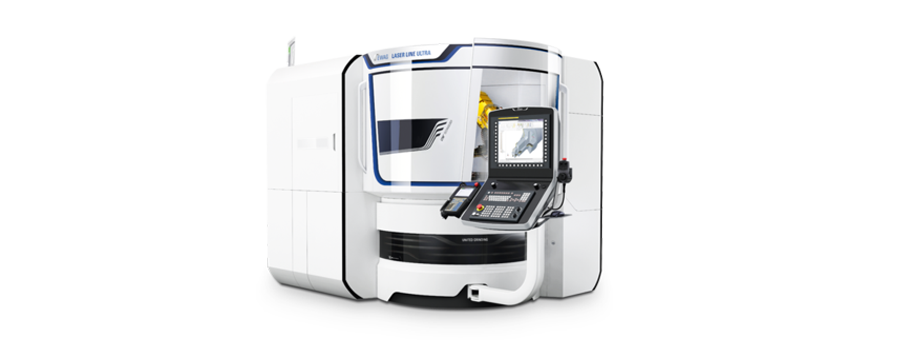

LASER LINE ULTRA – State-of-the-art ultra-short pulse laser technology for maximum flexibility

The LASER LINE ULTRA is a leading technological high-end laser machining unit for demanding applications. It has state-of-the-art ultra-short pulse laser technology, ensuring all cutting materials are machined carefully to produce exceptional quality. The EWAG Laser Touch Machining® Process (LTM®) achieves highly complex geometries with exceptional surface quality – in just one clamping operation. The LASER LINE ULTRA offers a great deal of flexibility thanks to its kinematics, 3D programming, ultra-short pulse laser technology and integrated automation.

The LASER LINE ULTRA carefully machines all commercially available cutting materials such as carbide, CBN, ceramic, PCD, CVD-D and MCD without producing heat, thus producing exceptional surface quality. It has a clamping range up to 200 mm in diameter and up to 250 mm in length, making it very versatile in its field and the first choice when a great deal of flexibility is required in applications.

Mechanical axes

| X axis | 440 mm |

| Y axis | 140 mm |

| Z axis | 170 mm |

| Rapid motion | 15 m/min |

| B axis | ± 100 ° |

| C axis | ∞ |

Laser source

| Industrial high-performance ultra-short pulse laser | 50 W / 100 W |

| Wave length | 1.064 nm |

| Repetition rate | 0,4 – 1 MHz |

| Pulse duartion | < 15 ps |

Others

| Power consumption at 400 V/50 Hz | approx. 11 kVA |

| Weight incl. robot cell | approx. 4.000 kg |

- Water reverse-flow cooling unit

- Automation with FANUC robot

- HSK 63 rack

- Pallets for rotating tools

- Pallets for indexable inserts

- Pallet changers

- Customised clamping solutions