STP FUTURA

STP FUTURA, SPERONI’s new product line for tool measurement and tool presetting is the expression of our 50 years’ experience in innovative technology. Our construction concepts, often imitated but never equaled, add new levels of ergonomics, ease of use and precision to the new STP FUTURA line.

The solid structure, together with our excellence in manufacturing, eliminates the need for frequent recalibration due to changes in temperature during the work shift, as well as guaranteeing the precision and repeatability of your system year after year. Due to this fact, software compensation – as offered by other presetter manufacturers – is not needed in order to correct mechanical misalignments.

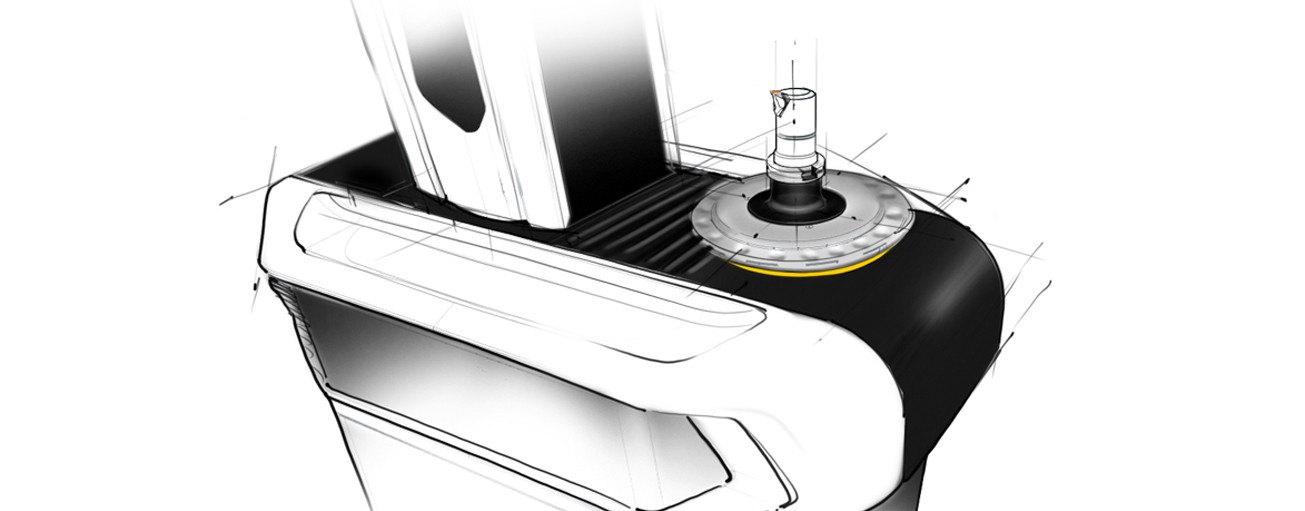

The high precision universal spindle, together with the rapid equipment change system, guarantees the highest precision and repeatability for all tool holders. The one of a kind universal mechanical clamping system, introduced in 1992, allows clamping any kind of tool with unequaled repeatability and precision.

- HOMOGENEOUS STRUCTURE

- MAXIMUM ERGONOMICS

- HIGH QUALITY PRECISION

- HEIDENHAIN® GLASS SCALES

- SONY® CCD CAMERAS

- MARCEL AUBERT® OPTICS

- SMC® PNEUMATICS

- BRAND PC AND PC BASED CONTROLS

- SPERONI ORIGINAL SPINDLE

- MANUAL OPERATION, AUTOMATIC MECHANICAL CLAMPING

- CNC SPINDLE

- CNC X AND Z AXES

- DATA OUTPUT (POST PROCESSOR)

- NETWORK CONNECTION

DESIGN AND PERFORMANCE

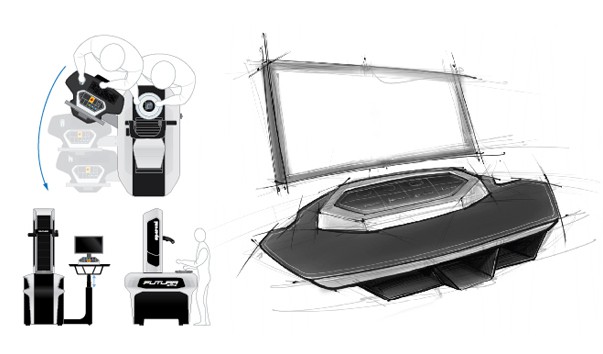

The modular design and high variety of available configurations offer the best solution for all needs, also guaranteeing the possibility of future updates in line with company growth. Our construction concepts add new levels of ergonomics, ease of use and precision to our STP FUTURA line. STP FUTURA’s innovative and original design received the Red Dot Award in 2014.

FOCUS ON ERGONOMICS

The new STP FUTURA establishes a new benchmark in the ergonomics field. The new cockpit allows operators to completely personalize their work station, maintaining the spindle concept completely accessible.

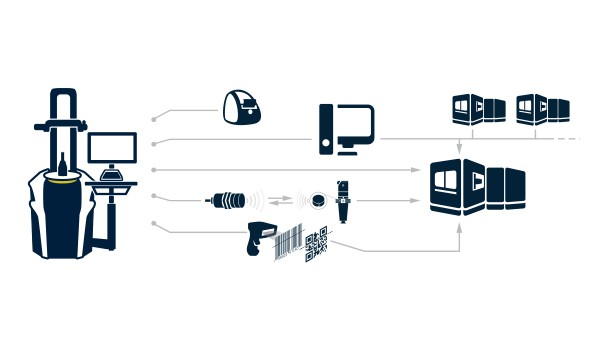

INTEGRATIONS

CONNECTIVITY – Simple and safe tool data transfer to/from machine tools: advanced dialogue with NC machines is available via RFID systems, QR codes, network and more.

CAM AND TMS INTEGRATIONS – Eliminate redundancy and facilitate tool data sharing between CAM and TMS systems.

MORE INFORMATION

INTELLIGO – SPERONI’s new Tool Management Solution Software to manage all your tools.

MORE INFORMATION

THE NEW CONTROLS ARE DESIGNED AND DEVELOPED ENTIRELY BY SPERONI AND THEY OFFER THE RIGHT SOLUTION FOR WHATEVER NEED WITHIN TOOL MEASUREMENT AND MANAGEMENT.

SIMPLE VISION

The newly designed graphic interface makes Simple Vision the most intuitive and easy to use control on the market today.

EDGE 2.0

The new image processing and control unit allows the upgrade to tool management, user management and integration with CAM interface.

EDGE PRO

The new image processing and control unit is available on manual and NC automatic systems. The integrated database allows for the management of components, tools, tool records, zero points and adapters. Together with NC axes, Edge Pro’s simple interface allows for the automatic measurement of all your tools.

RAPID AXES MOVEMENT DEVICE

ERGONOMIC KNOB FOR MICROMETRIC MOVEMENT

VERTICAL ROTATING INTEGRATED ISO50 SPINDLE

ERGONOMIC COCKPIT

INTEGRATED SHELF FOR EQUIPMENT STORAGE

HEIDENHAIN HIGH RESOLUTION GLASS SCALES