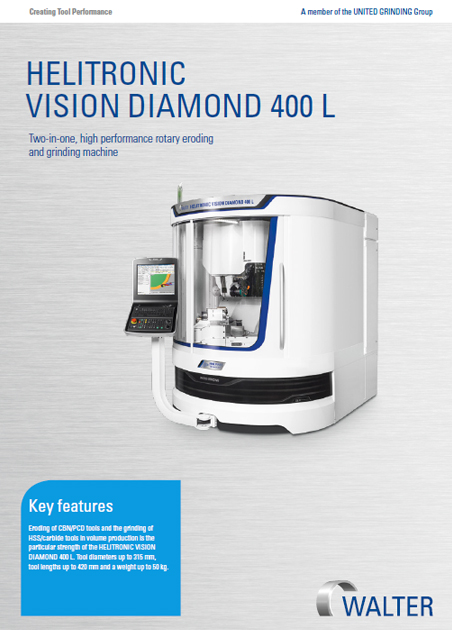

Two-in-one, high performance rotary eroding

Two-in-one: Two machines in one for the rotary eroding of CBN/PCD tools and the grinding of HSS/carbide tools, switching as you wish. The HELITRONIC VISION DIAMOND 400 L is the only eroding machine to combine linear and eroding technologies in a single machine. It machines complex geometries fully automatically with three rotating electrodes and three grinding wheels on a belt-driven spindle in one clamping cycle. This is just right for the high requirements of volume production.

Eroding of CBN/PCD tools and the grinding of HSS/carbide tools in volume production is the particular strength of the HELITRONIC VISION DIAMOND 400 L. Tool diameters up to 315 mm, tool lengths up to 420 mm and a weight up to 50 kg.

Mechanical axes

| X-axis | 500 mm |

| Y-axis | 350 mm |

| Z-axis | 700 mm |

| Rapid traverse speed X,Y,Z | max. 50 m/min |

| C-axis | ± 200 ° |

| A-axis | 750 min-1 |

| Linear resolution | 0,0001 mm |

| Radial resolution | 0,0001 ° |

Tool data

| Min. / Max. workpiece diameter | 3 mm / 315 mm |

| Max. workpiece weight | 50 kg |

Others

| Base | Mineral casting |

| Gross load weightz | approx. 7.000 kg |

| Connected load | 35 kVA |

Automation options

- Robot loader

- Robot loader 25

- Top loader

- Electrode/grinding

wheel changer 4/8 x - Electrode/grinding wheel changer 12/24 x

Software / Efficiency options

- ”Sketcher”

- “Feedrate Optimizer”

- “Quality Assurance”, etc.

Other Options

- Automated work table

- Grinding wheel dresser

- Sharpening stone holder

- Automatic grinding wheel measurement

- Automatic, electrical measurement of the machine reference

- Integrated Measurement System IMS etc.