This is our most sold unit around the world

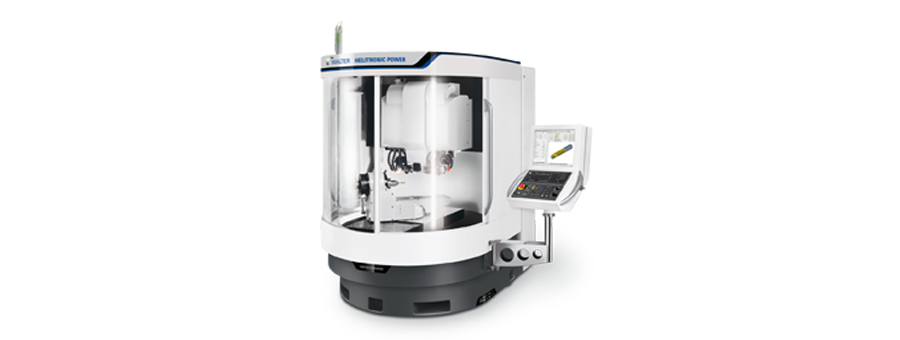

With up to six grinding wheels on the belt-driven spindle, the HELITRONIC POWER grinds complex geometries with only one clamping cycle. Together with the available loading systems, it sets standards in productivity and flexibility. Our customers appreciate these functions, which is why it is the best-selling WALTER tool grinding machine worldwide.

Around the world, the HELITRONIC POWER stands for top quality in the production and resharpening of rotationally symmetrical tools. Permissible diameters range from 3 to 320 mm, machining lengths can be up to 350 mm and each item may weigh up to 50 kg.

Mechanical axes

| X axis | 460 mm |

| Y axis | 320 mm |

| Z axis | 660 mm |

| Rapid traverse speed X, Y, Z | max. 15 m/min |

| C axis | ± 200 ° |

| A axis | ∞ |

| Linear resolution | 0,0001 mm |

| Radial resolution | 0,0001 ° |

Grinding spindle drive

| Max. grinding wheel diameter | 200 mm |

| Grinding spindle speed | 0 – 10,500 rpm |

Others

| Machine weight | approx. 4,200 kg |

| Power consumption at 400 V/50 Hz | approx. 25 kVA |

| Control | FANUC |

| Software standard | HELITRONIC TOOL STUDIO |

Loading systems

- Eco loader/Eco loader plus

- Chain loader 300plus

- Robot loader

Others

- Grinding wheel changer

- Frequency controlled pump 80 – 120 l/min at 7 – 20 bar

- Motor spindle 24 kW peak power with one end

- 750 rpm torque motor

- Glass scales

- High frequency spindle

- Heli Contour Check HCC

- Automated work table

- Software

- etc.