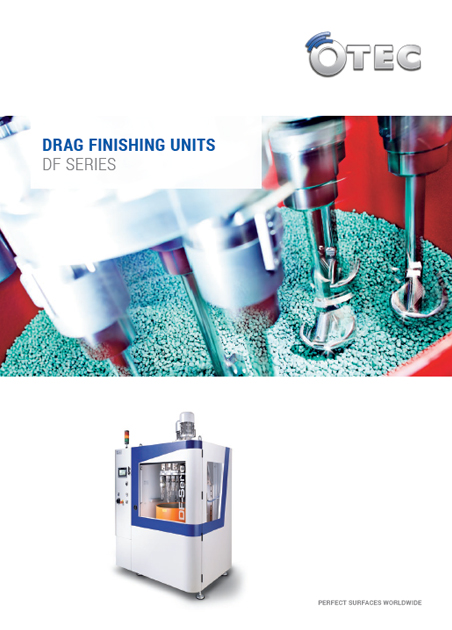

DRAG FINISHING UNITS – DF PHARMA SERIES

A stainless steel version with HD paintwork, the DF Pharma series was developed especially for surface finishing in the phramaceuticals and food industries and complies with the guidelines of these industries. Customized workpiece holders contribute greatly to the perfect finishing results obtained by the DF series and in addition to optimizing the clamping of workpieces, ensure fast mounting and batch changeover. In addition, the water cooling system of the process container keeps the polishing granuate at a consistently low temperature. This gives much longer service life and ensures that finishing results are consistent even at very high processing speeds.

- Absolute reliability Consistent use of only the best materials and components ensures trouble-free operation and long service life.

- Maximum cost-effectiveness Comparatively low capital investment coupled with the potential for very high cost savings in terms of processing times make the DF series an extremely cost-effective solution.

- Perfect finishing results Deburring, edge-rounding (even in the μm range) or high-lustre finish in a quality othwerwise only obtained through hand polishing.

- Short processing times In many cases, perfect surfaces can be obtained in just a few seconds.

DF PHARMA SERIES

Stainless steel cladding; Drive unit with HD paintwork. Complies with the guidelines for surface finishing in the pharmaceuticals and food industries. Availabe as DF 40 series (for finishing up to 36 workpieces); DF 80 (for finishing up to 60 workpieces).

STANDARD EQUIPMENT

- PLC control with touch screen

- Sturdy stainless steel frame

- Octagonal process container in stainless steel

- Standard mount for workpiece holder in stainless steel

- Speed control via frequency inverter

- Illuminated work area

- Hood

MISCELLANEOUS

Water cooling

to reduce the temperaure of the granulate

Trolley

for changing the process container

Holder for tabletting tools

Optimizing the angle of incidence ensures that the contact surfaces of the tools are polished evenly. The tools are locked in place in the tabletting tool holder by means of a quick-change coupling.

Attachment: Euro B: 12 workpieces/holder Euro D: 10 workpieces/holder Further workpiece holders for dies etc. are also available.

TESTS NOT PROMISES

Let us prove how good our technology is. We will be happy to put the performance of OTEC technology and the DF series to the test. We will give you detailed advice and develop a finishing concept tailored to your needs and formulate the best grinding and polishing media for your application. In addition, we offer to finish a sample workpiece for you with no obligation and to provide you wth a process log documentng all key process parameters.