DRAG FINISHING UNITS – DF SERIES

Custom-designed workpiece holders make a significant contribution to the perfect processing results obtained by the DF series. They also ensure that the workpieces are mounted as quickly and efficiently as possible and considerably simplify batch processing. In recent years, OTEC has designed over 100 different types of holder. Furthermore, the process container features a water cooling system which keeps the polishing granulate at a constantly low temperature. This considerably extends the life of the process medium and ensures constant process quality, even at consistently high processing speeds.

- Absolute reliability Consistent use of only the best materials and components ensures trouble-free operation and long service life.

- Maximum cost-effectiveness Comparatively low capital investment coupled with the potential for very high cost savings in terms of processing times make the DF series an extremely cost-effective solution.

- Perfect finishing results Deburring, grinding or high-lustre finish in a quality otherwise only obtained through hand polishing.

- Short processing times In many cases, perfect surfaces can be obtained in just a few minutes.

DF “WET” SERIES

Drag finishing machine for mass finishing and polishing of knee and hip joints, burr shafts, watch cases, dies, pistons and decorative workpieces.

STANDARD EQUIPMENT

- Process drum coated with PU to reduce wear

- High-quality sealed cladding in steel

- Flow-optimized process container

- Vertical spindle with ball screw drive for 90% on-time

- Display and selection of vertical workpiece position

- Infinitely variable drag finishing speed via frequency inverter

- Storage capacity for up to 200 process configurations

- Generous clearance between container rim and holder makes it easier to fit workpieces to holders

- Bearings for workpiece holders of up to 15 kg

- Process data can be backed up onto external MMC card

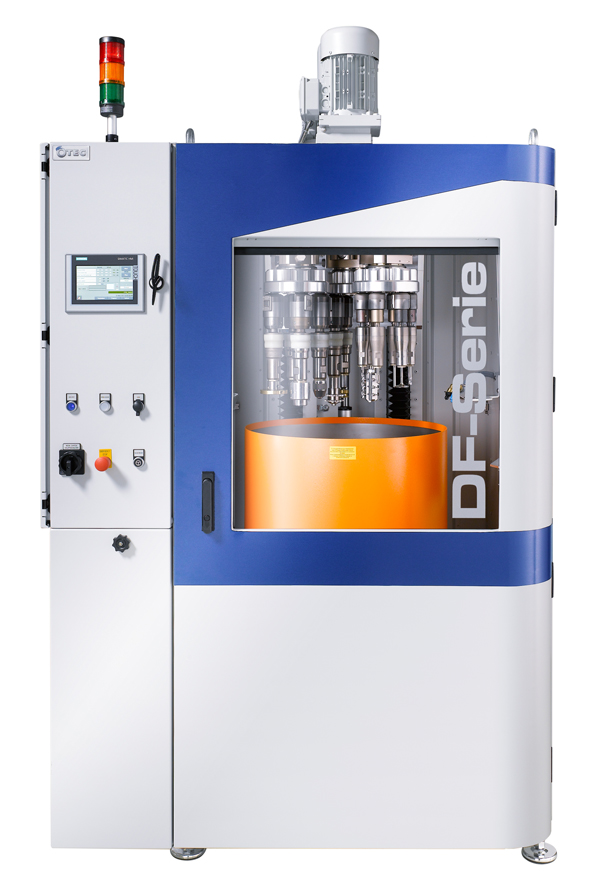

DF-3/4 HD SERIES

Drag-finishing machine for workpieces

STANDARD EQUIPMENT

- Process container with a capacity of 88 l

- High-quality, sealed cladding in steel, exterior of panels and base painted

- Flow-optimized process container

- Vertical spindle with ball screw drive

- Vertical workpiece position display and pre-selection

- Storage capacity for 200 process configurations

- Greater clearance between container rim and holder makes it easier to fit workpieces to holders

- 3 or 4 clamping devices for the workpieces holders S

- Stronger bearings for holding weights of up to 15 kg

- Process data can be backed up onto external MMC card

- Additional drive unit for independent holder rotation and higher speeds

- Automatic door for fast changeover of workpieces

DF-5/6 HD SERIES

Drag finishing machine for workpieces.

STANDARD EQUIPMENT

- Process container with a capacity of 114 l

- High-quality, sealed cladding in steel, exterior of panels and base painted

- Flow-optimized process container

- Vertical spindle with ball screw drive

- Vertical workpiece position display and pre-selection

- Storage capacity for 200 process configurations

- Greater clearance between container rim and holder makes it easier to fit workpieces to holders

- 5 or 6 clamping devices for the workpieces holders

- Stronger bearings for holding weights of up to 15 kg

- Process data can be backed up onto external MMC card

- Additional drive unit for independent holder rotation and higher speeds

- Automatic door for fast changeover of workpieces

DF-5/330 WET SERIES

Drag finishing machine for large and heavy workpieces. With its space-saving receptive workpiece holders and greater power, the DF-5/330 wet is one of our largest and most powerful DF machines..

STANDARD EQUIPMENT

- Process container with a capacity of 250 l

- For holder diameters of up to 330 mm and holder weights of up to 20 kg

- Maximum workpiece length 280 mm

- Sturdy, welded steel chassis

- High-quality, sealed cladding in steel

- Flow-optimized process container

- Vertical workpiece position display and pre-selection

- Storage capacity for 200 process configurations

- Greater clearance between container rim and holder makes it easier to fit workpieces to holders

- 5 clamping devices for the workpieces holders

- Process data can be backed up onto external MMC card

- Additional drive unit for independent holder rotation and higher speeds

DF3 S2 SERIES

The two-stage DF-3 S2 drag finishing machine from OTEC is a genuine innovation. For the first time ever, this machine makes it possible to grind and polish workpieces such as implants and watch cases whilst they are gripped in a holder. The advanced technology used achieves a finish equivalent to that obtrained by hand polishing but in an absolutely reliable process.

OTEC has been developing drag finishing machines ever since the company was founded in 1996. In this mass finishing process, the workpieces are clamped in holders and dragged trhough a grinding or polishing medium. To make the process even more effective, the workpiece also rotates on its own axis and at the same time describes a planetary motion.

In order to obtain maximum efficients, it is often necessary to process the workpieces in two stages. For example, the workpieces are processed by wet grinding in the first stage and then polished in dry process in the second stage. This enables Ra values of up to 0.01 µm to be achieved. Until now, this process required the use of two machines, e.g. on machine for wet grinding and another one for dry polishing, and this in turn meant repeatedly clamping and unclamping the workpieces.

The new DF-3 S2 solves this problem. The machine has two process containers which can be combned as required for wet/dry or dry/dry operation. The various process parameters such as finishing time, speed, etc. can be set by means of a Siemens touch screen panel. The machine then runs through all the individual processing stages, removing the need for time-consuming unclamping and reclamping of the workpieces.

HOLDER

Independently driven tool holders

With this type of holder specially developed for finishing tools, each workpiece rotates indivually on its own axis in addition to the general rotation. This produces a uniform surface finsh in even shorter processing times. It also achieves excellent smoothing of the flutes of cutting tools.

Angled holder

especially suitable for finishing end faces and forging dies

Quick tool changer

This system enables tools such as drills and burs to be changed in seconds by means of a lever.

TROLLEY

Trolley for DF Tools

Trolley with castors for quick container change

MISCELLANEOUS

Immersion depth control

For controlling the depth to which the workpieces are immersed in the granualte. Two photoelectric barriers are used to identify the tip of the workpieces when they are immersed in the medium. From this, the control system then calculates the maximum possible immersion depth. The immersion depth of the workpieces in the process container is displayed for any defined level of medium. The immersion depth of the workpieces can be preselected for best results.

Changing tray for attachments

Storage and changing tray for attachments (available in various sizes). Makes it easier to fit chucks and workpieces.

Hood

Hood for connecting an extraction unit

Water cooling

to reduce the temperature of the granulate

TESTS NOT PROMISES

Let us prove how good our technology is. We will be happy to put the performance of OTEC technology and the DF series to the test. We will give you detailed advice and develop a finishing concept tailored to your needs and formulate the best grinding and polishing media for your application. In addition, we offer to finish a sample workpiece for you with no obligation and to provide you wth a process log documentng all key process parameters.