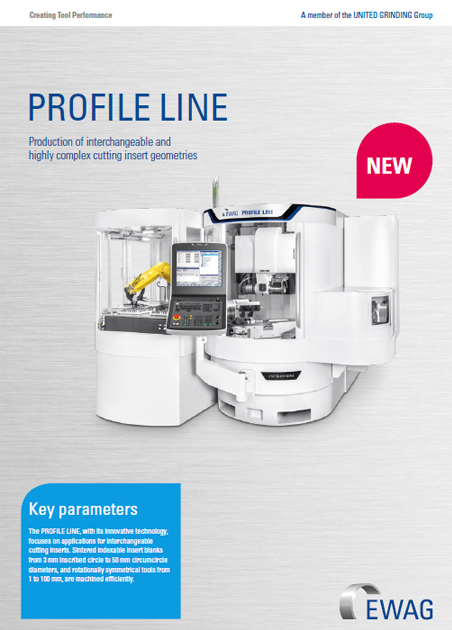

Production of interchangeable and highly complex cutting insert geometries

The PROFILE LINE, with its innovative technology, focuses on applications for interchangeable cutting inserts. Sintered indexable insert blanks from 3 mm inscribed circle to 50 mm circumcircle diameters, and rotationally symmetrical tools from 1 to 100 mm, are machined efficiently.

The PROFILE LINE is the grinding center for efficient production of highly complex interchangeable cutting insert geometries, ideally made of pre-sintered tungsten carbide blanks. The machine’s high efficiency, coupled with its autonomous multi-shift operation, is ensured by the smart integrated flexible FANUC 6-axis robot. The compact design of the grinding center supports optimal utilization of frequently limited production Areas.

Mechanical axes

| X axis | 330 mm |

| Y axis | 200 mm |

| Z axis | 470 mm |

| X, Y, Z rapid traverse | max. 15 m/min |

| C axis | ± 200 ° |

| A axis | ∞ |

Grinding spindle drive

| Max. grinding wheel diameter | 150 mm |

| Grinding spindle speed | 0 – 10,500 rpm |

Others

| Connected load at 400 V/50 Hz | approx. 25 kVA |

| Machine weight inclusive of coolant system | approx. 3.600 kg |

Coolant unit

- On request – more designs available

Loading systems

- FANUC 6 axis robot

Others

- Wheel changer, Vision System, magnetic gripper, cleaning stations, Software, etc.