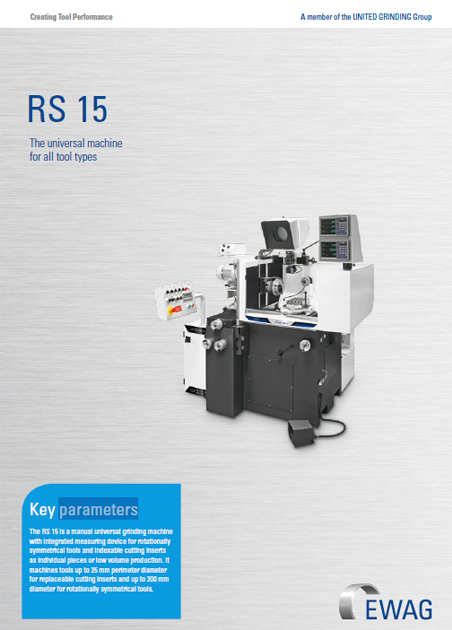

RS15 – Manual grinding technology with accurate grinding. Precise, productive and versatile!

The RS15 is a manual precision tool grinding machine, which enables cost-effective manufacture and machining of polycrystalline diamond and hard metal tools, HSS through to super hard PCD/PKBN as well as other tools, and regrinding of rotational cutting tools and indexable inserts. Thanks to the sophisticated kinematics, convex radii and tangents with constant, variable clearance angles up to 27° or constant profiles can be ground. The constant contact pressure is adapted to the stock removal volume and enables cost-effective grinding of super-hard materials.

Convincing advantages:

■ A notable increase in productivity is achieved, as tools can be measured directly on the machine by means of projector without reclamping.

■ The RS 15 guarantees the highest precision and a long working life, thanks to its robust and vibration-free design.

■ Measuring and grinding in a single clamping enables very high shape accuracy and increased production.

■ Increased productivity is achieved through direct measurement on the machine in combination with projector and digital display.

■ Diverse accessories enable grinding of convex and concave radii, spherical surfaces, multiple surface grinding on deep hole drills, and so on.

| Grinding spindle drive, three-phase motor kW (rpm): | 2,2 | |

| Speed range 1/min: | 1000…6000 | |

| X-axis, transverse adjustment mm: | 490 | |

| Speed variable rpm: | 100-1300 | |

| 102 mm / 25 kg: | 155×205 | |

| 102 mm / 25 kg: | 60 | |

| 102 mm / 25 kg: | 130 | |

| Y-axis, grinding stroke vertical, straight mm: | ||

| Z-axis, infeed stroke horizontal mm: | 120 | |

| Workpiece swivel axis A degrees: | -10 … +27 | |

| Workpiece swivel axis B degrees: | 240 | |

| Cross-slide U mm: | 100 | |

| Cross-slide W mm: | 100 |